Four Considerations When Determining How Much Inventory to Purchase

It's one of the most critical questions you'll deal with on a regular basis as an importer: how much inventory do you buy? Often the answer may be a simple ‘whatever the MOQ is'. Other times, the questions become more complicated and involve capital, warehouse space, and sales forecasting.

In this post, we'll discuss the basic considerations when deciding how much inventory to purchase from a Supplier.

The Most Basic Considerations

Some of the most basic considerations when deciding how much product to purchase from your Supplier are:

- What's the minimum amount that the Supplier will allow me to purchase (their MOQ)?

- What's the best amount to purchase to minimize my overall landed cost?

- What's the best amount to purchase to maximize sales and eliminate ‘out of stockages'?

- What's the best amount to purchase given the amount of cash I have and/or my cost of capital?

Lets take a look at all four of these scenarios.

What's the minimum amount that the Supplier will allow me to purchase (their MOQ)?

For many of us, especially when starting to import a new product, how much to order from a Supplier is an easy equation: order the least amount to meet the Supplier's MOQ.

This is an acceptable approach with a new product, especially when you want to determine if the product will have any sales traction. There's a couple of major pitfalls with this approach though:

- Ordering the bare MOQ normally means the highest prices from Suppliers

- Ordering the bare MOQ normally means the highest per unit freight costs

If you're ordering the Supplier's MOQ, it offers you little negotiation room. MOQ orders also mean you pay the highest per unit freight costs, especially for items going via sea (which we'll discuss further below). For these reasons, once you've determined that your product will sell well and you feel comfortable making a larger order, it's often wise to order more than the Supplier's MOQ.

What's the best amount to purchase to minimize my overall landed cost?

As you import larger and larger orders, you will achieve significant economies of scale.

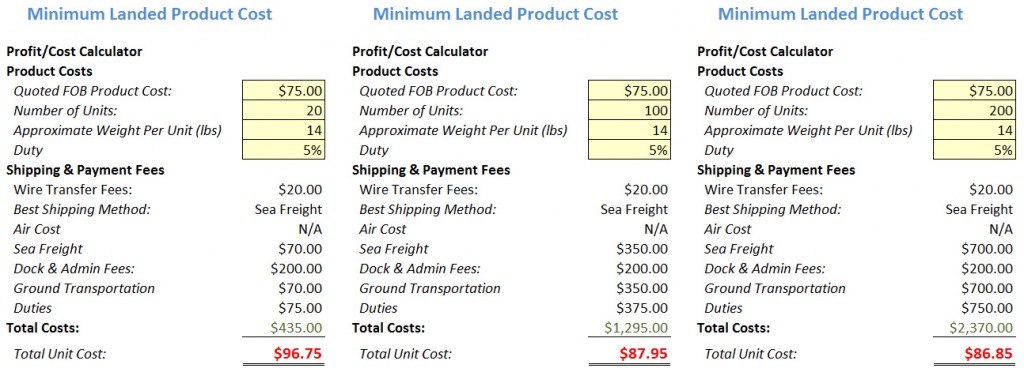

Imagine for example that we're importing a widget that costs $75 each. We're debating ordering the Supplier's MOQ of 20 units or making a larger order of 100 units.

Using the Minimum Cost Worksheet (available for free with the Importing from China is Easy eBook) we can estimate that by making a larger order of 100 units as opposed to 25 units, we can save nearly $9 per unit just on freight. On top of this, we could probably negotiate a slightly lower per unit cost from our Supplier as well, so the landed cost would be even greater than this.

You'll notice though that there is definitely a certain sweet spot for picking the optimal order size. An order of 200 units only saves about an extra $1 over an order of 100 units. Often, you'll see these break points between huge savings when you make the jump from having something shipped via air to LCL (Less than Container Load) Sea Freight and LCL Sea Freight to FCL (Full Container Load) Sea Freight.

What's the best amount to purchase to maximize sales and eliminate ‘out of stockages'?

Having to cancel orders because you've run out of stock of an item sucks big time. Worse is being out of stock of item for months during your busiest season.

In a perfect world where you have unlimited capital, unlimited warehouse space, and your products don't become obsolete, you would simply import 2 years worth of inventory. Of course though, we live in an imperfect world!

Myself personally, I like to order 3-4 months worth of inventory from each Supplier. Here's how I do my ordering:

- I take the estimated lead time for a Supplier (i.e. 60 days) and then forecast what inventory I will have on hand after that time frame

- I take a time frame I want to have inventory for, i.e. I'm buying for 3 months worth of product, and then look at how much of the product we sold of that SKU the previous year and then add 10%

- I make ‘gut feel' decisions on what I think may or may not sell for various reasons

This strategy is prone to misjudgments as you can imagine. It relies on making estimates for how much inventory I'll be able to sell over a given time and also estimating the lead time from Suppliers, both of which are subject to immense variation. In regards to the latter, if I can give you one word of advice it is that Wang's Law (Wang was a distant cousin of Murphy) states that the amount of time you think it will take your inventory to get from China to your doorstep will always be at least 50% longer than you anticipated. I have imported hundreds of shipments in my life from China, and I can literally count on two hands how many arrived sooner than I expected. Causes for late shipments include: massive floods in Ningbo, lengthy customs examinations, port strikes, and simple Supplier tardiness.

What's the best amount to purchase given the amount of cash I have and/or my cost of capital?

If you only have $10,000 then you know the maximum amount of inventory you can purchase: $10,000 (and actually quite a bit less once you take into account freight, duties, etc.). Often, however, one's cash situation isn't quite as granular. Consider, for example, that you have a $10,000 Line of Credit with a 10% interest rate. You're considering importing a product but you will have to use this Line of Credit to purchase it. Theoretically, if you can sell your product for a greater return than 10% per year, then it's wise to use this Line of Credit, and if your return is less than 10%, you should skip the order.

Doing cash flow projections are absolutely critical to ensure your business is healthy. Many accountants will agree that it isn't lack of profitability that kills many businesses, it's cash flow problems. I've gone through periods where my business was as profitable as ever but the business came under serious risk due to cash flow problems. Most businesses that have been around long enough have run into similar problems.

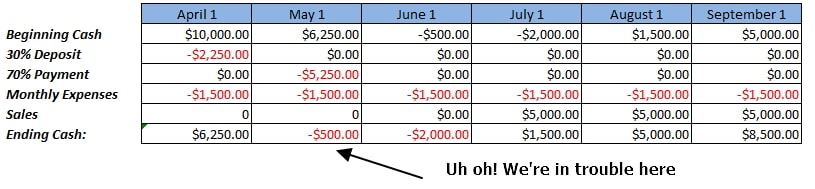

Consider again that you have $10,000 to spend on inventory so you make an order with your Supplier for $7500. You estimate that it will take you 3 months to sell that inventory and you can sell it for twice as much as you purchase it for (so in 3 months you double your money- not bad!). You have monthly fixed cost expenses of $1500. Without further examination everything looks dandy, but in reality, you are going to have serious cash flow problems!

By May 1 we will be $500 short of enough money to cover our expenses. By June 1 we will be $2000 in the negative. If we can hold on until September 1 you will have $8500 in the bank even after paying 6 months of expenses.

The problem is that normally our Supplier wants us to pay a small deposit of 30% upfront. OK, that's not bad. And then they want us to pay 70% once the shipment is complete. Fine, that sounds fair. But unfortunately once the shipment is complete it will take 30 days+ by the time we can actually sell it.

The conclusion from the above scenario is that we need to either a) make a smaller order or b) arrange to have an additional $2000 of cash available.

Conclusion

Purchasing is one of the most important hats you'll wear as an importer. Over the years, I would like to think that I've managed to develop better intuition and strategy behind making orders with my Suppliers. However, each year my company still either misses out on thousands of dollars worth of sales from under-ordering or we get thousands of dollars tied up in slow moving inventory from over-ordering. So in conclusion, like many things in business, I don't think purchasing is something one ever stops learning at. Hopefully though with the above considerations you're able to plan your purchases all that more effectively.

Have you had purchasing wins or fails? Have you imported way too much of a product and been stuck with it sitting in your garage for months on end? Have you nervously made a large order and have it sell as well as you anticipated? Please share your experiences in the comments below.